Recycled collision parts, despite perceptions of low quality, meet or surpass OEM standards through strict testing and inspections. Using them is an economic and eco-friendly choice, reducing raw material needs, manufacturing emissions, and waste, extending component lifespans. While often cheaper than new or aftermarket parts, their true cost-effectiveness depends on quality, warranty, and safety standards, which vary; rigorous inspections and warranties from reputable suppliers make them a competitive option.

“Unraveling the mysteries surrounding recycled collision parts, this comprehensive guide debunks common myths and provides insights into their reliability, sustainability, and cost-effectiveness. With growing concerns about environmental impact and budget constraints, understanding the truth behind recycled parts is essential for informed decisions. From stringent quality assurance processes to significant cost savings, we explore why these ‘second-life’ components are a smart choice for both consumers and the planet.”

- Quality Assurance: Are They Really Reliable?

- Environmental Impact: A Sustainable Choice

- Cost Savings: Debunking Price Misconceptions

Quality Assurance: Are They Really Reliable?

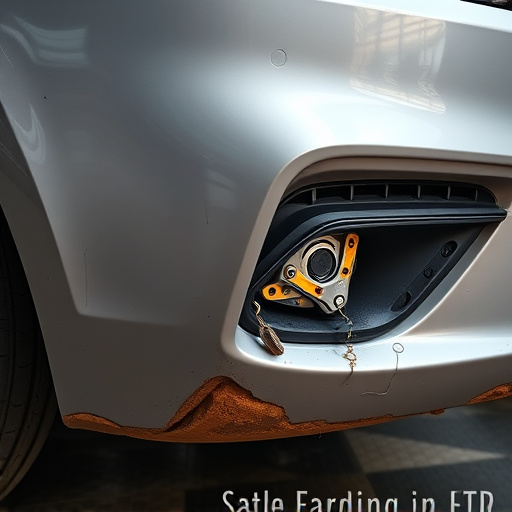

Many believe that recycled collision parts lack quality assurance, but this couldn’t be further from the truth. Reputable suppliers adhere to strict standards and rigorous testing procedures to ensure each part meets or exceeds original equipment manufacturer (OEM) specifications. This includes comprehensive inspections, material analysis, and performance evaluations to guarantee reliability and safety.

The misconception often arises from a misunderstanding of the term “recycled.” It doesn’t imply second-rate or unsafe; instead, it refers to parts that have been salvaged from vehicles involved in collisions but subsequently restored to like-new condition through meticulous fender repair and automotive body work. These processes involve replacing damaged components, refinishing, and retesting, ensuring that recycled collision parts are just as dependable as their new counterparts when used in professional automotive repair services.

Environmental Impact: A Sustainable Choice

Using recycled collision parts is an eco-friendly choice that goes beyond mere cost savings. The environmental impact of this practice is significant. By repurposing materials from damaged vehicles, we reduce the demand for new raw resources, minimizing extraction’s harmful effects on ecosystems and communities. This process also cuts down on manufacturing emissions, as less energy is required to produce parts from recycled materials.

Moreover, proper recycling and reuse extend the lifespan of automotive components, diverting them from landfills where they can leach toxic chemicals into the soil and water. Many collision repair centers now prioritize using recycled collision parts in their services, positioning themselves as responsible stewards of the environment while offering high-quality car dent removal and fender repair solutions. This sustainable approach aligns with the growing global efforts to reduce waste and promote circular economy principles, ensuring a cleaner future for generations to come.

Cost Savings: Debunking Price Misconceptions

Many believe that recycled collision parts are significantly cheaper than new or aftermarket ones. While cost-effectiveness is a primary driver for many car owners to opt for recycled parts, it’s important to understand that price doesn’t always tell the whole story. The notion of substantial savings may be a myth; recycled collision parts can often match or even exceed the prices of new components, especially when considering the overall cost of auto repair services and fleet repair services.

The truth lies in the fact that used parts from collisions are typically priced lower because they’re considered secondary market goods. However, their availability, quality assurance, and warranty vary widely. Unlike some aftermarket parts that might be cheaply made or lack proper testing, recycled collision parts go through rigorous inspections to ensure they meet safety standards. Moreover, many reputable suppliers offer warranties on these parts, protecting car owners from unforeseen costs associated with auto glass repair or other repairs, which can sometimes offset the initial price difference.

In debunking common myths about recycled collision parts, it’s clear that these components offer a reliable, sustainable, and cost-effective solution for vehicle repairs. Through rigorous quality assurance processes, environmental benefits, and competitive pricing, recycled collision parts are not only a responsible choice but also a practical one. Embracing this practice helps reduce automotive waste, minimize environmental impact, and promote a more circular economy, ensuring that old cars parts find new life on the road.